We are Agent for Baltur Leading manufacturing Natural Gas & Light Oil Burner in Italy. We have maintenance center, stock from many Capacity and Different fuel burners' uses in industrial application, Bakery oven, boilers

:Light oil burners

(Single stage operation (on/off

Compatible with any type of combustion chamber

High pressure mechanical atomisation of fuel using nozzle

Ability to obtain optimal combustion values by regulating combustion air and blast-pipe

Maintenance facilitated by the fact that the atomisation unit can be removed without having to remove the burner from the boiler

Manual air flow adjustment

Comes with a 7-poles connector, 2 flexible oil pipes, 1 nozzle, 1 oil filter, 1 flange and 1 insulating seal to connect the burner to the application

(wo-stage operation (high/low flame

Compatible with any type of combustion chamber

High blowing efficiency, low electrical input, low noise

High pressure mechanical atomisation of fuel using nozzle

Ability to obtain optimal combustion values by regulating combustion air and blast-pipe

Combustion head at partial recycle of combusting gas which allow to achieve low Nox emissions (Class II for BTG 15 ME and class III forBTG 20 ME of the european norm EN267

Maintenance facilitated by the fact that the atomisation unit can be removed without having to remove the burner from the boiler

Air flow regulation for first and second stage by means of hydraulic jack

Comes with 4 and 7-poles connectors, 2 flexible oil pipes, 2 nozzles, 1 flange and 1 insulating seal to connect the burner to the application

: Natural Gas Burner

(Single stage operation (on/off

Compatible with any type of combustion chamber

Air-gas mixing at blast-pipe

Ability to obtain optimal combustion values by regulating combustion air and blast-pipe

Maintenance facilitated by the fact that the mixing unit can be removed without having to remove the burner from the boiler

Manual air flow adjustment

Possibility to choose gas train with valve tightness control

Comes with a 7-poles connector, 1 flange and 1 insulating seal to connect the burner to the application

(Two-stage operation (high/low flame

Compatible with any type of combustion chamber, according to EN303 standard

High blowing efficiency, low electrical input, low noise

Air-gas mixing at blast-pipe

Maintenance facilitated by the fact that the mixing unit can be removed without having to remove the burner from the boiler

Low NOx and CO gas-fired burners, EN676 "Classe III"

Burnt gas recycling blast-pipe able to achieve very low pollutant emissions, particularly with regard to nitrous oxides (NOx)

Regulation of air flow rate for first and second stage with damper closure on standby to prevent in-flue heat dispersion

Gas regulation by means of a two-stage working valve that is electromagnetically driven

Ability to add a valves seal control device to the train

Comes with 4 and 7-poles connectors, 1flange and 1 insulating seal to connect the burner to the application

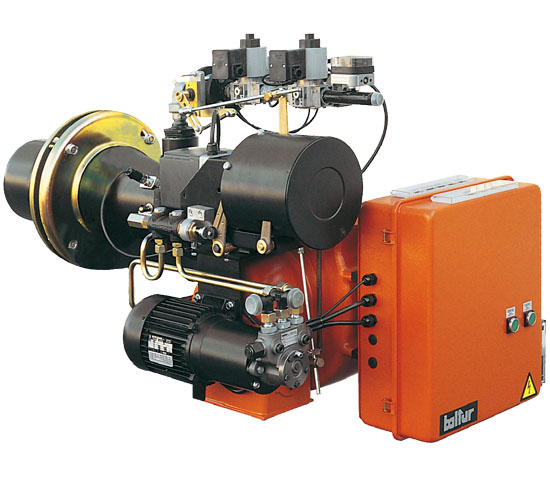

: Dual Fuel Burners

Two Stage gas \ light oil burners dual operating mode